steel ball dropping impact tester|impact and drop testing : makers The Ball Drop Test is a simple and convenient way of imparting a known impact force to test the strength of various materials. web22 de nov. de 2022 · Raluca Pop, also known as Kassandra Pop, is a student living in Southern California and the founder and creator of the Hive Social app. "Sometimes it's tricky for people to pronounce, so I just go .

{plog:ftitle_list}

Resultado da Plot SummaryA young Mexican man's dream comes true when he gets the job of a lifetime at the hottest resort in Acapulco. But he soon realizes the job .

Impact testing. Haag engineered this unique system to impact target locations precisely on every drop. Our AccuDrop® steel ball tester helps perform UL 2218 tests faster, using fewer test . The steel ball drop test is used to determine the impact force of a falling object on a surface. It is commonly used in materials testing and engineering to evaluate the strength . This video demonstrates UL-60950 ball-drop test on Promate Diamond Series 7" and 12" Touch Display module, using a half-kilo (542g) steel ball dropped from a height of 1.3 .A simple test method of measuring impact force versus displacement, and then integrating for the area under force-displacement curve provides an output in energy units.

The Ball Drop Test is a simple and convenient way of imparting a known impact force to test the strength of various materials.The most frequent impact test hammer is a precision mild steel ball. The ball is held at a specific elevation by an electromagnet. The high magnetic permeability of this low carbon mild steel provides good magnetic holding power.

The Impact Test Ball is a specially machined ball to test impact resistance according to IEC, CSA and UL Standards. It is made of chrome-plated-steel for durability, and is fitted with an eyelet to facilitate testing for pendulum .This method has been used for decades for evaluating impact resistance of wood panels and other building materials. It involves a 2-inch steel ball weighing 1.18 lbs (535 g) dropped from 1 to >12 inches.

what is impact testing

Ball impact tests are used to assess the impact resistance of components and these involve dropping a steel ball of a specified mass through a tube from a specified height onto a . The steel ball drop test is commonly used in product development to test the durability and impact resistance of materials. It can help engineers and designers determine the strength of a material and make necessary improvements to ensure its reliability and safety in real-world applications. Shown here is a Steel Ball Drop Test per UL60950 requirements. The optical bonding . Optical bonding of an LCD prevents the display from cracking or breaking. Shown here is a Steel Ball Drop .

Dropping Ball Impact Tester. Send us an Inquiry. Description. The specimen is placed on the platform of machine. Choose a designated size of steel ball to fall freely from a height, then the steel ball will impact on specimen’s surface. Observe the specimen of damaged condition on its surface. The test height and the size of steel ball can be .

Ball impact tests are used to assess the impact resistance of components and these involve dropping a steel ball of a specified mass through a tube from a specified height onto a horizontal surface of the component that is being tested. . Our solution is the Bertrandt Ball Impact Device, a portable piece of test equipment that fires a ball . The test specimen in a drop-weight impact test is notched, and the weight is dropped on the surface opposite that of the notch. Like the other impact tests previously described, the drop-weight impact test is frequently used to test for a material’s ductile-to-brittle transition temperature. 4. Dynamic Tear TestAn alternative method which can be used is the ball drop impact tester (BIT) in accordance with MIL-STD-1751 A, method 1016 [5]. Similar ball drop impact testing devices are mostly used in the US. In this method, a free-falling steel ball is dropped onto an unconfined layer of substance. This testing scenario takes more realistic circumstances intoImpact and Drop Testing . On the other hand, if the same steel ball is dropped on to a steel plate, it may rebound back to the same height to which is was originally dropped. Thus, very little energy is absorbed. The impact force is very large and a .

This 50mm diameter Impact Test Ball weighing 500 grams is a specially machined ball to test impact resistance according to IEC standards below, as well CSA and UL standards. It is made of chrome-plated steel for durability, and is fitted with an eyelet to facilitate testing for pendulum applications. Ergonomics can also supply this ballImpact testers, capacity: 1 kg, automation grade: manual; Steel toe impact test, automation grade: automatic; Anand 0.5hp / 0.35kw v and u notch broaching machine for imp. Aiv testing aggregate impact tester with blow counter, for l. Bevs: ce certified tubular impact tester, model name/number:. Pendulum Impact Testing with Impact TestersThis ball drop tester is used to measure the impact resistance by the specified steel ball at specified height. It applies for ceramics, acrylic, glass, plastic and etc. Dongguan ITM-LAB Machine Inc. specializing in ball dropping test,impact testers,impact testing machines.

Complies with all IEC, EN, UL, CSA and International Standards which require a 50mm diameter, 500g impact ball. This ball is hardened steel with a chrome finish and is provided with a removable eyelet to allow for drop or pendulum use. Model ITB-03 is the same as ITB-01 except for a 2 in. diameter and 1.18 lb [.]The Drop Ball Impact Test is a widely-used method of evaluating the impact resistance and overall toughness of various materials like plastics, glasses, ceramics, and even metals. . To conduct this test, a steel ball with a specific weight is dropped from a predetermined height onto the material being tested. Operation Method for drop weight impact tester : Press the drop button, The sucker/ cupula release the ball, Steel ball will be free fall test, Impact on the specimen surface exactly. Drop height can be adjusted up and down, With a height gauge, you can see the parts drop height. These are the fully process on simulate the drope weight impact test.

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends on .

EI-1704 Steel Ball Drop Impact Tester, for plastic, ceramic, acrylic, glass fiber coating materials and testing of fastness, ball weights optional 50,100,150,200,300,500,800,1000g +606 6030 951 / +6012 2216 210

In 1996, the Institute of Business and Home Safety (IBHS) and the Underwriters Laboratory (UL) developed the UL 2218 classification, a national standard for roof impact resistance by rating materials Class 1 through Class 4, based on their resistance to the steel ball drop simulation test. A Class 4 rating is the toughest.A test inspired by Robert Bastow when he commented on anvilfire by saying, "You could bounce a 1" steel ball off the monitor!". Obtain a steel ball bearing ball (1/2" (13mm) to 1"(25mm)) in diameter. Drop (DO NOT THROW) the ball .Dropping Impact Tester Confirm to JIS-A5403, K6745 Standard The specimen is placed on the platform of machine. Choose a designated size of steel ball to fall freely from a height, then the steel ball will impact on specimen’s surface. To observe the .

We are best Steel Ball Dropping Test Device suppliers,we supply best Steel Ball Dropping Test Machine for sale. We would like to establish the long term win-win relationship with customers from all over the world. . the steel ball is suspended by a cord and swung as a pendulum in order to apply a horizontal impact, dropping through a vertical .In the test, three test specimens were prepared for each steel ball weight, and the impact force was calculated using Equation (6) from the weight of the steel ball that broke the specimen in at .

net work during impact testing

Several researches were conducted using the RBDWI test on different types of concrete reinforced with different types of fibers. Natadaja et al. [13] investigated the impact resistance of SCC reinforced with crimped steel fiber with fiber length of 27.5 mm. Nili and Afroughsabet [1] studied the influence of the inclusion of silica fume on the impact resistance .

38mm Steel Ball for Tempered Glass Testing Steel Ball 2260g 227g 1040g 508g 227g Ball drop test device for safety glass Steel Ball: 2260g±20g 82mm Steel Ball: 1040g ±10g 63mm Steel Ball: 508g±3g 50mm Steel Ball: 227g±2g 38mm. Various testing equipment such as shot bags / twin tires and impact frame, 227 and 2260 g steel ball and ball drop impact devices, .The ball drop experiments were carried out using the BIT-132 ball drop impact tester (OZM Research, Czech Republic) 25 following MIL-STD-1751 A (method 1016) 5. A steel ball (0.50–2.00 inch, 8.35–534.70 g) is rolled of a steel guidance and dropped onto the explosive compound with a certain spin.The Steinfurth Ball Impact Tester allows standardized impact tests for bottle closures. The bottle to be tested is held in a box, which can be swung from a horizontal to a vertical position in steps of 5 degrees. Operation: The impact weight, a steel ball with defined mass and diameter, is manually dropped through a drop pipe.

Steel ball drop impact testers apply for steel ball impact tests for mobile phones, PDAs, digital cameras, and electronic dictionaries. It can check the anti-impact strength. Product Specification MODEL XB-OTS-2000A Impact capacity 20gf, 30gf, 50gf, 100gf or specified Effective dropping height 300~1000mm Control method Electric Dimension (WxDxH .The Ball Drop Impact Test BIT 132 is designed for impact sensitivity test of all types of energetic materials using falling steel balls. AOP-7, MIL-STD-1751A

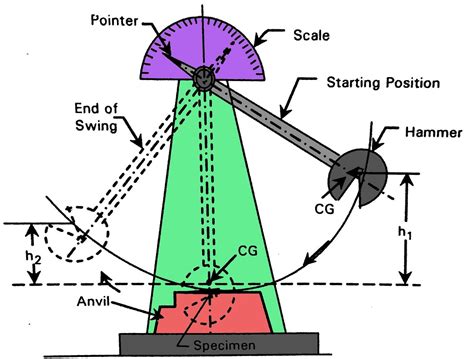

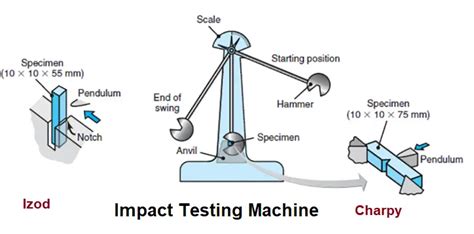

Pendulum Charpy/Izod Impact Testing is a high strain-rate test to determine the amount of energy absorbed by a material during fracture.The Impact tester involves a pendulum of known mass and length which is dropped from a known height to strike an Impact Specimen. . Ball Rebound Tester; Steel Ball: 16.3±0.2g: Ball Diameter: 16±0.2: Sample .

salt spray chamber china

impact testing examples

Resultado da Description lapushe. Hey, honey! I'm Lapushe, a 22 years old brazilian girl and adult content creator. I'm so excited to be your daily tease! 😇 ️. Subscribe and get access to: Photos and videos everyday. Chat with me any time you want. Hot Tiktok. Gifts in your chat.

steel ball dropping impact tester|impact and drop testing